Safety Bulletin | Concrete vs. Steel

SAFETY AND DESIGN BULLETIN

Concrete vs. Steel: Why Steel Silos Fail

Introduction

download the Jenike Independent Report Early storage silos, primarily used by farmers for the bulk storage of corn, were built using wood, brick, stone, or galvanized steel throughout the late 19th century. The use of concrete for the construction of storage silos revolutionized the industry in the early 20th century and expanded the use of storage silos beyond the farm. Today, both steel and concrete silos are commonly used in industry for the storage of ash, coal, lime, aggregate and more. While often less expensive upfront, steel silos have inherent limitations and pose a number of safety risks.

download the Jenike Independent Report Early storage silos, primarily used by farmers for the bulk storage of corn, were built using wood, brick, stone, or galvanized steel throughout the late 19th century. The use of concrete for the construction of storage silos revolutionized the industry in the early 20th century and expanded the use of storage silos beyond the farm. Today, both steel and concrete silos are commonly used in industry for the storage of ash, coal, lime, aggregate and more. While often less expensive upfront, steel silos have inherent limitations and pose a number of safety risks.

Severe wind toppled metal silos

Limitations of Steel

Steel silos are susceptible to internal and external corrosion from abrasive storage materials and moisture. They require frequent maintenance and expensive painting. Improper design can often lead to substantial problems and increased safety risks. The factory made metal components come together quickly, but careless detailing of metal walls can leave inward facing ledges or welds that obstruct flow, increase wall pressure and lead to splitting or bursting of metal silos. Bolted connections are also likely to leak fine powders. In addition to these safety risks, the increased flexibility of steel silos enables easy bending or collapse from strong winds.

Steel silos are more vulnerable to weather conditions like rain, humidity and high winds. To reduce the risk of high winds, topography can sometimes be taken into account for the design of steel silos. Understanding when hillsides produce a sheltering effect or leave silos exposed to high winds can help reduce some risk steel silos face in high winds.[i]However, even with proper planning, large storms with severe winds are inevitable. In fact, the number of steel silo failures due to wind continues to rise.

Storm damaged silo in Frisco, TX

Corroded silo in Loudoun County, Virginia

The first part of 2016 held numerous examples of the dangers posed by steel silos. High winds have led to several damaged or destroyed silos across the country. Severe storms in Frisco, Texas on March 8, 2016 downed one steel silo and weakened another. Both silos were deemed structurally unsound after the destruction and required removal and replacement.[ii] A farmer in Hardin County, Ohio faced close to $1 million in damages when several grain storage bins were destroyed in a heavy wind storm on March 27, 2016.[iii] Wind damage is not limited to older steel silos. On April 3, 2016, two brand-new steel silos were toppled in Darlington, Wisconsin, closing the nearby road for several days.[iv] Older silos do, however, have a greater likelihood to develop corrosion that can lead to property damage, serious injury and death.

Yet even when silo design fits the application and topography perfectly, it still requires proper inspection and maintenance—regardless of construction material. Concrete silos require minimal maintenance as they are not typically weakened by abrasive or corrosive materials, or moist environments that lead to rusting in steel. When steel silos experience wall thinning from abrasive storage materials, corrosion from internal or external moisture compounds the risks of silo failure. In August 2015, a steel silo holding 500 tons of sand particles collapsed in Loudoun County, Virginia, killing an 18-year-old worker. According to news reports, investigation into the cause of collapse cited corrosion and a lack of regular inspections by the owner.[v]

Conclusion

Overall, concrete offers numerous advantages and provides better structural stability than steel or aluminum in the construction of storage silos. Concrete better resists internal pressure that causes buckling, splitting and other failures of steel silos like abrasive internal wear from stored materials and corrosion. Using concrete in place of steel for the construction of storage silos eliminates these risks when combined with proper maintenance and inspection.

Steel structures regularly battle costly corrosion issues and damage from high winds while concrete silos require no exterior painting or cleaning and are not susceptible to rust or collapse from wind. Concrete repair is often far more convenient as it can usually be conducted externally, while repair of steel silos often must be done internally. This leads to costly down-time as silo content must be temporarily relocated. Concrete silos, coupled with proactive silo inspection and maintenance, improve safety and cut product losses.

Pros of Concrete and Cons of Steel:

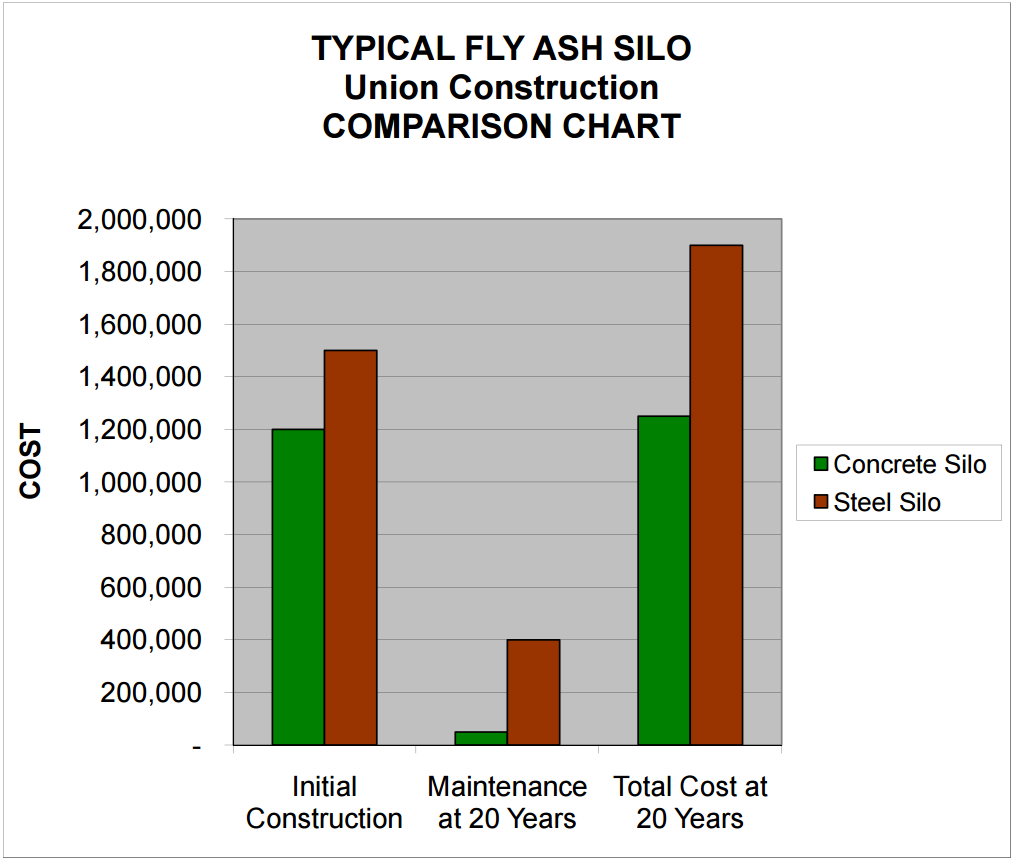

- Concrete silos are typically lower in cost than metal silos over their respective lifetimes.

- Concrete silos have good resistance to corrosion. This includes both corrosion of internal walls due to the stored bulk solid and also external corrosion caused by moisture. Metal corrosion is a well-known problem.

- No need for expensive painting of silos due to corrosion thus lowering operational cost.

- There is no concern about electrolytic effects at welds or liner connections.

- Careless detailing of metal walls may leave inward facing ledges or welds, which can obstruct flow and increase wall pressures. This is avoided with concrete.

- Concrete is better able to resist abrasive wear than most metals.

- Concrete is more robust and thus better able to withstand internal pressure loads and impact loads.

- Concrete has higher wall friction angles with most bulk solids than most metals. This results in higher frictional drag down the cylinder walls and hence lower pressures acting normal (i.e. perpendicular) to cylinder and hopper walls.

- There is no concern about weld quality or stress risers, such as bolted connections.

- There is no concern about leakage to the environment.

[i] Mobley, R. Keith. Plant Engineer's Handbook. 4-19. Boston: Butterworth-Heinemann, 2001.

[ii] "Frisco Plans to Tear down Grain Silos after One Collapsed during Tuesday's Storms." Frisco Enterprise, March 10, 2016. Accessed April 14, 2016.

[iv] Bolin, Evan. "Silos Toppled, Road Closed in Darlington." WKOW, April 3, 2016. Accessed April 14, 2016.

[v] MacFarlane, Scott. "'Corroded' Parts One Reason Silo Collapsed in Loudoun Co., Killing 18-Year-Old: Federal Report." NBC Washington, January 14, 2016. Accessed April 14, 2016.