Silo Repair Case Histories

Stave Silo Repair for Aggregates Storage - Florida

Marietta Silos worked on five silos that were constructed with concrete staves and utilized steel galvanized hoops around the silo for structural integrity.

Silo Roof Beam Bearing Repair - Florida

Beam pockets are a critical point on the silo as these roof beams hold up the silo roof slab and all the necessary equipment to operate the bulk storage system.

Stave Silo Wall Repair - Florida

To add structural integrity to the existing silo before failure, a collar wall utilizing reinforced, poured in place, concrete jump-form technology was added.

Suspended Steel Silo Cone Repair for Coal Storage - Pennsylvania

The suspended cone broke loose from the silo walls and fell straight down, destroying all the discharge equipment below and blowing out the silo wall. Due to the damages, this silo was deemed irreparable by professional engineers.

Wood Chip Concrete Silo Wall Repair - Louisiana

Steel galvanized hoops were installed around this silo's weak zone to try to prevent failure and keep the wall intact.

Grain Concrete Silo Wall Repair - Ohio

Steel galvanized hoops were installed around the weak zone to help prevent failure. Failure was due mainly to the initial design of the silo.

Cleaned and Coated 3 Limestone Silos - Texas

Three concrete silos coated with a specifically designed cementitious coating with a bonding agent.

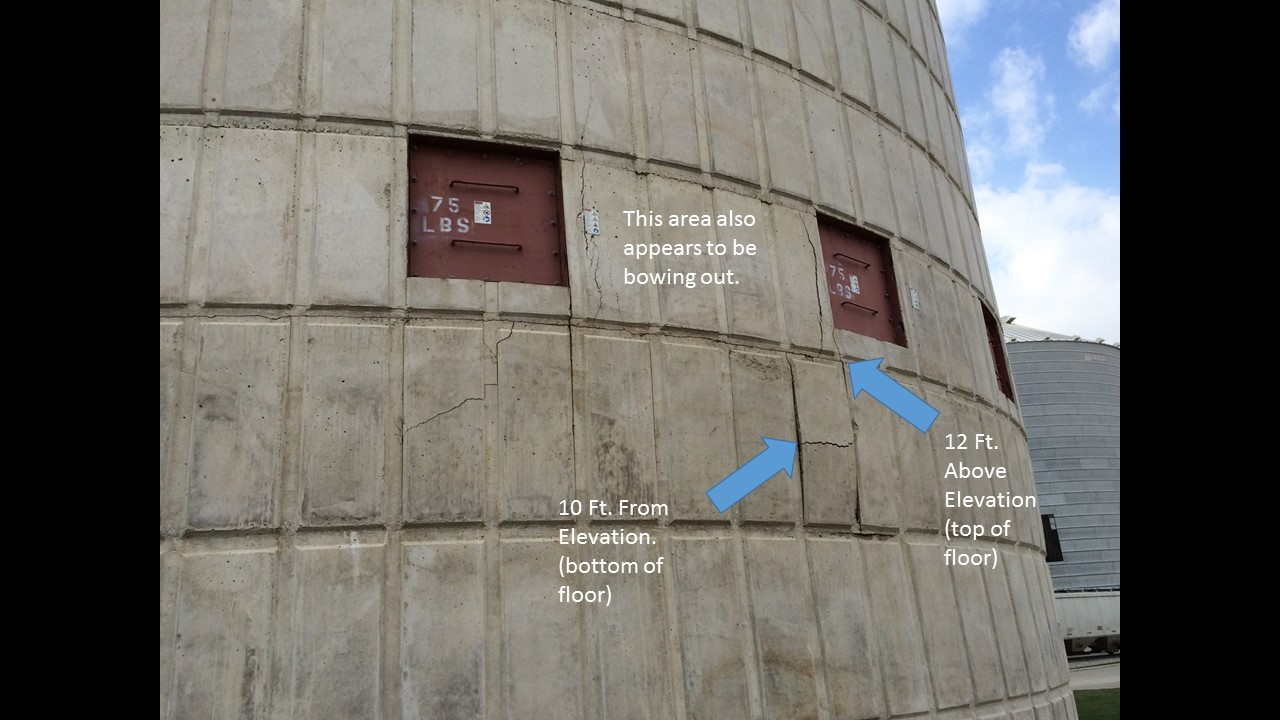

Bulging and Cracked Stave Silo Walls with Broken Frame - Pennsylvania

It is imperative that stave silos be inspected regularly to ensure their safe, efficient operability.

Cracking and Broken Stave Silo Repair - Pennsylvania

It is imperative that stave silos be inspected regularly to ensure their safe operability.

Repair of Silo Cracking and Delamination from Asymmetric Flow - Illinois

Repairs needed when the asymmetric flow caused concrete delamination and exterior concrete began to crack.

Cracking Stave Silo Repair - Texas

In the manufacturing process, these silos are in constant use. This, coupled with the stave silo design, makes regular inspections and preventive maintenance supremely important.

Repair of Improper Lime Stave Silo Coating - Texas

A cementitious silo coating is ideal on concrete stave silos as it protects the steel galvanized hoops and prevents leakage.

Silo Repair of Rusted Hoops, Broken Staves and Wall Failure - Oklahoma

Rusted hoops, broken staves and wall failure could have been prevented with regular inspections.

Sawdust Silo Repair Following Silo Explosion - Kentucky

Marietta Silos was called in to repair this silo after sawdust ignited and blew up.

Aggregate Silo Wall Failure Repair - Pennsylvania

It is imperative that stave silos be inspected regularly to ensure their safe operability.

Aggregate, Sand and Gravel Stave Silo Repair - Alabama

On this silo, the conveyor loading system was designed to attach at the roof edge. This connection to the first two silos coupled with standard movement and settling over time led to the cracking issues.

Silo Repair of Cracking Silo Pedestal - West Virginia

This silo's pedestal is in need of repair as it is displaying significant cracking along the horizontal members.

Clay Powder Silo Roof Repair - Georgia

This concrete stave silo was modified incorrectly from a bucket conveyor for filling material into the silo to a pneumatic filling system.

Steel Hopper Liner Silo Repair - North Carolina

Regular inspections can help prevent devastating outcomes.

Leaking Concrete Silo Roof

Many facilities have concrete silos that end up leaking due to membranes, similar coverings or a reliance on the concrete slab alone. Coverings like membranes are susceptible to water penetration as they develop holes and other points of intrusion over time.

Leaking Aircraft Hanger Metal Roof

In addition to concrete and steel silos, Marietta Silos offers waterproof coating for a variety of metal structures. In this case, the metal roof on an aircraft hanger building was leaking.

Corroded Bolted Steel Silos, Tanks or Vessels

Corroded bolted steel silos, tanks or vessels should be repaired to avoid leaking or other failure. For this repair, the silos suffered from extreme corrosion and risked leaks due to a compromised gasket.

Grout Finish on Two Clarifying Units - KY

Clarifier tank bottoms need a smooth top layer of grout to allows for increased flow of bottom ash.

Post Tension Solution for Silo Damage Caused by Asymmetrical Flow - Arizona

Resolving structural problems from asymmetrical flow requires an engineered solution.